Face to Interface: A2SF’s "Temping" is an uncanny, moving performance for one

I double-checked that I was at the correct address, but the unmarked doors to the office building were locked.

After I tried the handles one more time to see if there was something I had missed, an extremely polite office worker let me in and gave me a welcome packet and some paperwork to sign.

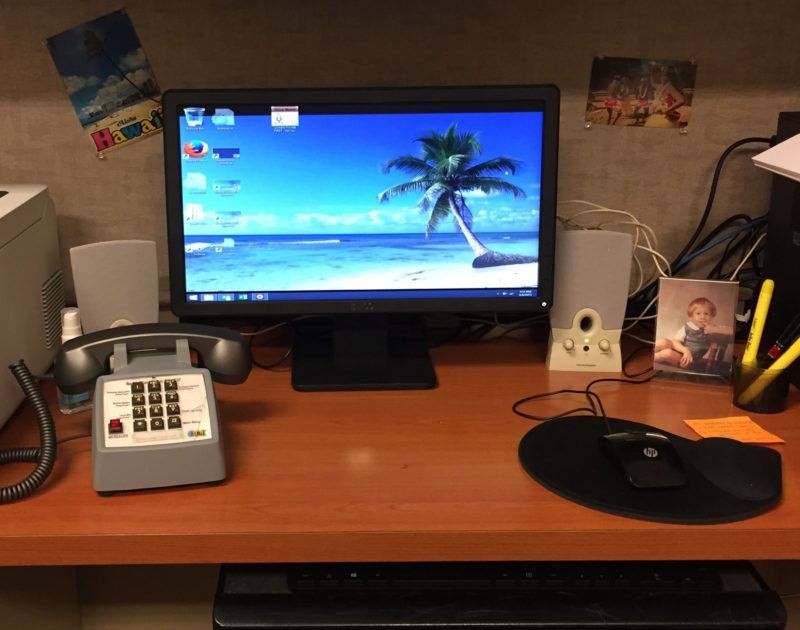

At my appointed time, I was ushered into an isolated cubicle with the usual setup—computer, printer, shredder—but also, family pictures, sticky notes, and office cartoons.

However, I was not here to work but to watch a performance. Or was I the performer?

This is Temping, a show for one that is part of this year's Ann Arbor Summer Festival.

Much like an actual temp job, the show plunks you down into an already-established office eco-system and gives you little training or context for the tasks you are asked to complete. As you receive voicemails, printouts, and emails, you begin to understand your new job: filling in as an actuary for the firm Harold, Adams, McNutt, & Joy. While Sarah Jane Tully is on vacation, it is now your job to mark her clients’ employees deceased or estimate their life expectancy.

Quarantine Binge: The wonderful world of webcomics

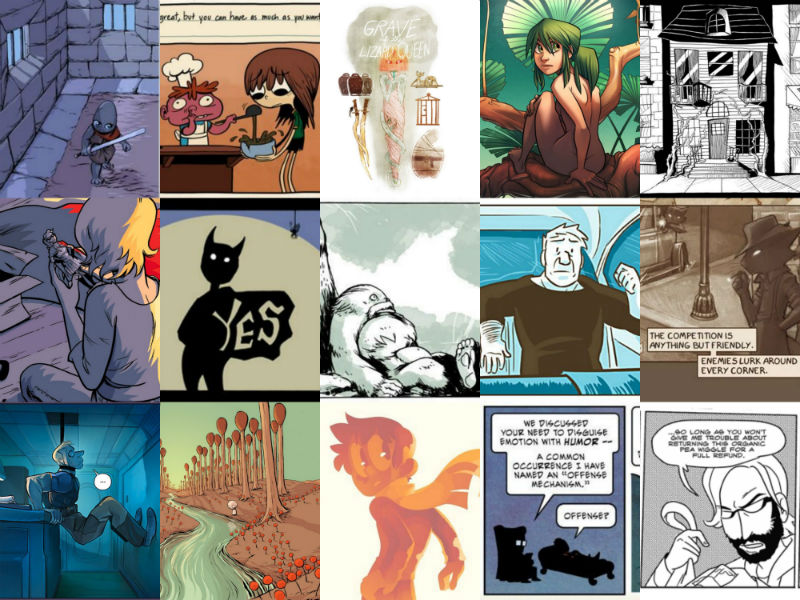

Perhaps you’re finding that you have watched all the TV and movies that you can and you’ve read all your books. What to do? I suggest the eminently bingeable genre of webcomics, which are pretty much just like regular comics but just posted online. For free.

Even if you generally don't read comics and graphic novels, I suggest looking through a few webcomics and seeing if you like them -- most are very different from traditional superhero comics. And, hey, this pandemic is leading a lot of people to try something new. I tried savory oatmeal because I ran out of bagels and found out that it was great, so maybe you’ll get sucked into the fantastic art and stories that these comics have to offer.

You can split webcomics into roughly two categories: daily strips and graphic novels. Certainly, there are a lot of comics that don’t fit into either category, but a lot of popular webcomics like XKCD, Saturday Morning Breakfast Cereal, Strange Planet, and Dinosaur Comics feature one-pagers frequently. These are like popcorn and you can easily spend a day or two reading the massive backlog of these comics. But the comics I’m going to feature here are mostly of the graphic novel variety. They are long stories in which each page contributes to an over-arching plot.

This is just a teeny sampling of the webcomics out there and those linked below are my personal favorites. When it comes to webcomics, there really is something for everyone and a growing diversity amongst stories and creators. Comic artists are generally very generous about promoting each others' work, so if you find an artist you like, see whose work they recommend.

Also, blanket advisory: with a few exceptions, all of these comics deal with mature themes. If you are in the (very understandable) mood for mindless fluff, this is not the list for you. But if you want to find some stories full of complex characters, adventures, ethical dilemmas, and amazing art, any comic listed here is a great place to start. If a comic sounds intriguing but you’re worried about disturbing content, you may want to do a bit of research about it first.

The link to each comic goes to the first page of the story.

Wooly Business: Stephany Wilkes tracks the fall and potential rise of the U.S. wool industry

When Stephany Wilkes became a knitter in 2007, she walked into a yarn shop and asked, “Where’s your local yarn section?” The shop attendant pointed her to a single brand of U.S.-made yarn. Nine years later, when I walked into a yarn shop for the first time, much had changed. I had several U.S.-made yarns to choose from -- even some Michigan-made yarns -- but found myself asking another question: “Why is this so expensive?”

The answer, as I later found, is that milling wool grown in the U.S. is so costly that most ranchers either send their wool overseas to be processed or use the fleeces as compost. Due to decades of adverse agricultural and trade policy, the cost of processing wool in the U.S. is very high. Wilkes' book, Raw Material: Working Wool in the West (Oregon State University Press, 2018), tells us how the bottom fell out of the U.S. wool industry and also shows us the way back to environmentally beneficial and economically profitable U.S. wool.

As for Wilkes, once she learned that a key factor in the high cost of U.S. wool is the lack of qualified shearers, she did the only logical thing: became a shearer herself. Raw Material is Wilkes' account of her unlikely career change from a software engineer at a San Francisco firm to a self-employed sheep shearer and wool classer. Along the way, she introduces us to many of the people who are working against the odds to bring U.S. wool back to life and make wool profitable for farmers and affordable for handcrafters.

I got the chance to talk to Wilkes in advance of her November 5 appearance at the Ann Arbor District Library.